Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

First of all you should know the structure of the trolley

Hydraulic and mechanical can be selected. After analysis and comparison, the hydraulic type has low requirements for rigidity of the trolley frame, sensitive structure, light weight, low processing requirements and low elevation requirements of the laying track during construction, and is convenient to use, but it has high requirements for the self-locking of the hydraulic cylinder. The hydraulic cylinder in the lining does not Allow retraction.

The mechanical type is the opposite. Because one motor needs to drive several screw drives, the coaxiality of each drive shaft is required to be high, and the trolley frame must have greater rigidity, and the structure and size must be accurate. Due to the heavy structure and high processing requirements, And because the lead screw is synchronized action (unlike hydraulic transmission, each hydraulic cylinder can be synchronized or independently), when the track elevation error (each point is not at the same elevation) is large, it will directly affect the template orientation and then affect the lining quality .

After analysis and comparison, the hydraulic transmission plan is selected, and measures such as hydraulic lock and balance valve are adopted for the hydraulic cylinder to make the hydraulic cylinder self-locking; together, the screw organization is selected for mechanical determination, and the support of the template is strengthened to ensure that the template does not return during lining. Shrink without deformation. Practice has proved that it is reasonable to choose hydraulic type for lining trolley, which is the development direction.

Trolley frame structure optimization

The trolley adopts hydraulic transmission, which simplifies the structure of the trolley frame and reduces the weight. At the same time, it also improves the sensitivity and diversity of the structure. After analysis and comparison of various trolley frame structure plans, strength calculations, and optimization, the 9m four-door frame 12m is selected The main mast structure plan reduces the structure weight by more than 40% compared with the mechanical type, and reduces the manufacturing cost by more than 25%.

Steel mold steel mold is the operating equipment of the trolley. Its surface quality and external dimension accuracy directly determine the quality of the concrete lining. Together, it is the most difficult part to process. Reasonable processing and welding technology have been formulated, and special assembly welded tires have been planned and processed. Die to ensure the accuracy of the overall dimensions, minimize welding distortion, ensure lubrication of the surface, and no defects such as height.

In order to control the misalignment of adjacent templates, the stabilizing pins of interference cooperation are used to fix the connecting plates of adjacent templates as a whole, which effectively controls the misalignment of adjacent templates caused by the gap of the bolt holes. After successfully solving the above-mentioned problems, the quality of concrete lining is ensured.

Determination of bearing position

The entire mass of the lining concrete is transmitted to the supporting organization through the steel mold of the trolley, and then to the portal frame. The lining concrete is in a solid-liquid state. Large vertical pressure and lateral pressure are generated on the top and side, and a large buoyancy occurs together. When the buoyancy exceeds the straight pressure and the weight of the trolley, the trolley will float up. Will not work normally.

In order to deal with this technical problem, after careful calculation, optimized planning, and reasonable selection of each supporting position. That is, the lower longitudinal beams inside the mast are supported on the ground to prevent the side pressure from causing the mast columns to retract, and there are several horizontal supports on the outer side of the mast and the longitudinal beams of the side form, at the upper beam and the upper longitudinal beam of the mast Several straight supports are selected (the top hydraulic cylinders are arranged on the horizontal part of the gantry at both ends, and the middle is a straight supporting screw), which is uniformly distributed in the longitudinal direction of the trolley.

The hydraulic cylinder is determined by hydraulic lock, and the supporting screw is used for mechanical determination, which ensures that the hydraulic cylinder does not retract and the template does not deform during the lining construction.

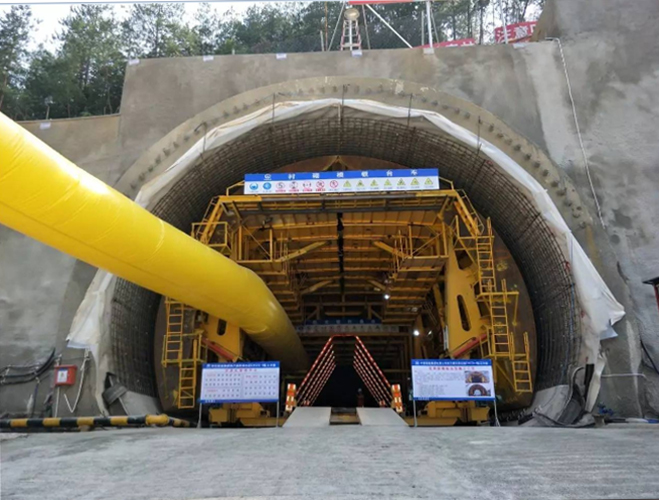

Tunnel Lining Trolley: The Lining Formwork Trolley (referred to as the trolley) is the construction equipment for pouring the secondary lining concrete of the tunnel. Cooperating with other auxiliary machinery, it can greatly reduce the labor force, improve the mechanization efficiency of the tunnel second lining construction, and improve the construction progress. It has investment It has the advantages of low cost, reliable structure, convenient operation, and good tunnel forming surface. Therefore, it is widely used in the construction of highways, railways, water conservancy and hydropower, municipal, national defense and military engineering.

According to the different tunnel engineering, the lining trolley is divided into side-top arch type, straight wall variable cross-section side-top arch type, abrupt surface type, full circle needle beam type, full circle travel type, etc. According to the actual needs of the user, the fully hydraulic self-propelled, fully hydraulic dragged, mechanical Steel Formwork, simple combined formwork and other types can be selected. The length of the trolley can be selected according to the length of the tunnel and the construction period of 6 meters, 7.5 meters, 9 Meters, 10.5 meters, 12 meters, etc.

In addition, everyone knows that if we just use anything without paying attention to maintenance, it will affect its performance and even its service life. How should the Tunnel Trolley be maintained in daily life?

1. After the tunnel trolley works for 15 working cycles, replace the hydraulic oil and reduce the oil.

2. Grease the screw jacks in each working cycle to remove the concrete on the surface of the portal frame, jacks and formwork.

3. Mold release agent must be applied to the template during each working cycle.

4. The piston rod of each cylinder must be covered when pouring concrete to prevent concrete from falling on the surface of the piston rod.

5. After each demolding, check whether the connecting bolts are loose, and tighten them if they are loose.

It is best to pay attention to prevent the oxide pickup from getting stuck in the furnace wire to cause a short circuit. At the same time, check whether the over-temperature alarm and temperature measurement system are normal. Don't forget to maintain it after the work is completed to extend the utilization rate.

LET'S GET IN TOUCH

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

Fill in more information so that we can get in touch with you faster

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.